The article author is making a few good pointers on the subject of Fix a Broken Toilet Flange as a whole in this content down below.

Introduction:

Recognizing the Importance of a Toilet Flange:

In the realm of plumbing, the often-overlooked commode flange plays a critical duty in making sure the smooth operation of your washroom components. Acting as a vital connector in between your commode and the underlying drain, the bathroom flange functions as the unrecognized hero of your plumbing system. Without this durable component, your commode would be prone to instability and leaks, potentially resulting in expensive fixings and hassle. Consequently, understanding the value of a properly mounted and preserved toilet flange is extremely important for any property owner embarking on plumbing tasks or addressing repair work needs.

Why Proper Installation and Maintenance Matter:

Appropriate installation and meticulous maintenance of the commode flange are essential for securing the stability of your plumbing framework. A carefully mounted flange not only anchors your commode securely in position yet additionally forms an impervious seal, warding off the dangers of leakages and smells. By accepting an aggressive approach to flange upkeep, you can mitigate the risk of disruptive plumbing issues and maintain the tranquillity of your home setting. Throughout this informative guide, we'll unwind the complexities of toilet flange installation and repair work, empowering you with the understanding and know-how to navigate these crucial tasks expertly.

Best Practices When Installing a Toilet Flange:

Making sure a smooth toilet flange installment calls for adherence to a set of finest practices that assure resilience and functionality. Begin by thoroughly examining your tools and products, guaranteeing you have the essential tools for the task ahead. Selecting the appropriate flange product, whether PVC, ABS, or cast iron, is critical, as it establishes the longevity and efficiency of your plumbing component. Furthermore, evaluating existing plumbing problems, such as looking for damages or rust, is vital for preemptively addressing potential problems and guaranteeing a smooth setup procedure. By adopting these preparatory measures, you set a solid structure for an effective toilet flange setup, minimising the probability of future problems and assisting in long-term maintenance.

Once appropriately ready, proceed with the careful elimination of the old flange, complying with an organized strategy to prevent causing damage to surrounding components. Utilize methods customized to resolve stubborn or rusted flanges, ensuring their swift and secure elimination without compromising the stability of the bordering plumbing infrastructure. With the old flange got rid of, diligently set up the new substitute flange, picking one that fits comfortably and securely into place. Properly safeguarding the flange to the flooring utilizing screws or adhesive is vital, as it ensures security and stops future leaks. By adhering to these ideal techniques during the installation process, you prepared for a robust and trustworthy bathroom flange setup that stands up to the test of time.

Setting Up a New Toilet Flange:

- Choosing the Right Replacement Flange

- When installing a new toilet flange, the very first step is to select the right replacement for your plumbing setup. Think about aspects such as the product of the flange, with options including PVC, ABS, or cast iron. PVC flanges are known for their cost and resistance to corrosion, making them a preferred choice for DIY lovers. ABS flanges provide similar benefits to PVC but brag added durability, making them suitable for high-traffic areas or business setups. Cast iron flanges, renowned for their toughness and long life, are optimal for installations where durability is extremely important. Additionally, guarantee that the replacement flange is effectively sized and fits snugly into location to produce a leak-proof seal and protect against leaks.

Securing the Flange to the Floor:

Once you've picked the right substitute flange, it's critical to secure it correctly to the floor to make certain security and stop future issues. Begin by placing and straightening the flange properly over the drain, guaranteeing that it sits flush with the flooring surface area. Depending upon the type of flange and your particular installation choices, you can protect the flange to the floor making use of screws or adhesive. If utilizing screws, be sure to make use of corrosion-resistant options to avoid rusting with time. Conversely, adhesive can supply a safe and secure bond in between the flange and the flooring, making sure a strong and trustworthy installation. By following these actions and taking the necessary safety measures, you can install a brand-new bathroom flange with confidence, making sure a durable and leak-free plumbing fixture.

Finest Practices When Repairing a Broken Flange:

Repairing a damaged toilet flange demands thorough interest to detail and adherence to ideal techniques to ensure a long-term remedy. Begin by extensively examining the degree of the damage and recognizing the underlying reason, whether it be rust, splits, or misalignment. This evaluation will assist your repair work method, enabling you to choose the most proper strategies and materials for bring back the flange to its optimum condition. Furthermore, take into consideration the bordering plumbing infrastructure and flooring security to attend to any possible contributing variables and protect against future issues from emerging. By conducting an extensive analysis and analysis, you prepared for an efficient and long-lasting repair work procedure that resolves the origin of the issue.

With a clear understanding of the flange's condition and the elements influencing its damages, proceed with the fixing process using precision and treatment. Depending upon the extent of the damages, you may go with repair methods such as epoxy putty, repair work flange sets, or partial flange substitutes. Make certain that the picked repair work method successfully attends to the particular problems at hand while keeping the structural honesty and functionality of the flange. In addition, take positive procedures to reinforce the repaired flange and protect against future damages, such as applying sealer or waterproofing materials to safeguard versus leaks and deterioration. By sticking to these best methods during the fixing process, you can recover your busted flange to optimal condition, ensuring the lasting integrity and efficiency of your plumbing system.

Kinds Of Toilet Flanges:

Recognizing the different types of commode flanges is essential for choosing the most suitable choice for your plumbing needs. PVC, ABS, and cast iron are among the common products made use of in commode flange construction, each offering distinct benefits and considerations. PVC flanges, understood for their cost and deterioration resistance, are favoured for their convenience of installment and longevity. Abdominal muscle flanges, similar to PVC in regards to cost and convenience of installment, are treasured for their robustness and resistance to influences. On the other hand, cast iron flanges, renowned for their remarkable stamina and longevity, are frequently favored for high-traffic locations or industrial setups where longevity is paramount. By familiarising yourself with the attributes of each product, you can make a notified choice when selecting a bathroom flange that aligns with your details demands and preferences.

Along with material factors to consider, toilet flanges additionally come in different design and styles to fit various plumbing configurations and installation preferences. Offset flanges, for instance, are made to fit commodes set up on floors that are uneven or where the drain lies off-centre. In a similar way, repair work flanges, likewise known as repair service rings or spacer rings, are used to deal with issues such as broken or damaged flanges without the requirement for extensive plumbing modifications. Additionally, adjustable flanges provide adaptability ready, enabling exact placement and fit throughout installment. By checking out the diverse range of commode flange kinds and designs readily available, you can pick the option that ideal suits your plumbing arrangement and installment requirements, ensuring a smooth and trusted remedy for your restroom components.

Specialized Options:

Along with standard toilet flanges, there are specialty options offered to resolve certain plumbing difficulties and setup preferences. One such choice is the countered flange, which is made to suit bathrooms mounted on floors that are not level or where the waste pipe is located off-centre. Offset flanges include an one-of-a-kind layout that allows the toilet to be placed at a small angle, making up for irregular floor covering or misaligned plumbing connections. This innovative remedy makes sure a safe and stable setup, eliminating the requirement for expensive and taxing floor progressing or pipe moving. By incorporating an offset flange into your plumbing configuration, you can get over typical setup challenges and accomplish a professional-quality result easily.

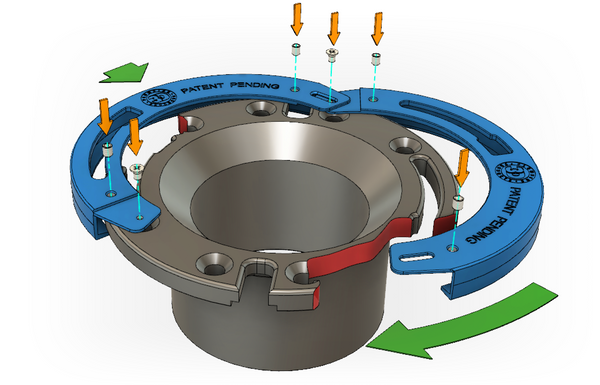

An additional specialty alternative worth considering is the fixing flange, additionally known as a repair work ring or spacer ring. Repair flanges are specifically created to deal with concerns such as split or broken toilet flanges without the demand for comprehensive plumbing adjustments. These versatile elements can be mounted straight over the existing flange, providing a strong and dependable base for safeguarding the toilet in position. Repair flanges come in numerous sizes and configurations to accommodate various flange sizes and installment needs, making them a practical and cost-efficient remedy for dealing with flange-related issues. Whether you're dealing with a minor flange repair work or a more complicated plumbing issue, integrating specialty options like countered and repair work flanges can enhance the installment process and make certain durable efficiency for your shower room fixtures.

Verdict:

To conclude, grasping the art of toilet flange installation and fixing is crucial for preserving a functional and leak-free plumbing system in your home. By understanding the value of a correctly installed flange and sticking to best techniques throughout the process, you can ensure the longevity and integrity of your restroom components. Whether you're choosing the best type of flange, performing repairs, or exploring specialty options, interest to information and careful implementation are key. Normal upkeep and positive repairing can help stop costly plumbing issues and preserve the serenity of your family atmosphere. Armed with the expertise and skills gained from this comprehensive guide, you can tackle commode flange installation and fixing with confidence, equipping you to safeguard your plumbing system for several years ahead.

How to Install a Toilet Flange on A Concrete Floor

Preparation in Installing or Replacing a Toilet Flange

- Gloves

- Screwdriver

- Hacksaw or a power saw

- Measuring tape

- Putty knife

- Hammer

- New screws (if needed)

- New T-bolts (if needed)

- New wax ring (if needed)

Remove the Old Flange

The first step is to remove the old flange. You can unscrew the bolts that hold the flange in place. If the bolts are rusted or stuck, you may need a grinder to get them out.

Once the bolts are out, you should be able to pull the flange out if needed. You can try prying it out with a screwdriver or a putty knife if it’s stuck.

Scrape off the Old Wax Ring

Now that the flange is out, you need to remove the old wax ring. You can do this by scraping it off with a putty knife. Be sure to get all of the wax off so that the new wax ring will adhere properly.

Clean the Area around the Drain

Once the wax ring is removed, you need to clean the area around the drain. This will ensure that the new flange is attached appropriately.

You can use a brush and some soapy water to clean the area. If there is any rust or build-up, you may need to use a power drill with a wire brush attachment to remove it.

Measure the Size of the Flange

Now that the area is clean, you need to measure the size of the flange. This will ensure that you get the correct size flange for your toilet.

Most flanges are either 3 or 4 inches in diameter. To measure the diameter, you will need to use a tape measure.

Select the Correct Size Flange

Once you know the diameter of the flange, you need to select the correct size. If you’re not sure which size to get, you can always ask a salesperson at the hardware store for help.

One way to ensure that you get the right size flange is to take the old one to the store. Just make sure that the old flange is clean and free of any wax or build-up.

Set the Toilet Flange in Place

The next step is to set the new flange in place. You will need to align the flange with the drain to line up the bolt holes. It would help if you also considered the distance from the wall.

Most flanges are designed to be installed about 12 inches from the wall to the center of the flange. However, you may need to adjust this based on the size of your toilet. Our favorite flanges to install are twist in flanges which you can pick up from your local Home Depot. You can check them out here.

Drill Holes for the Screws

Once the flange is in place, you need to drill holes for the screws in the concrete. You will need to use a concrete drill bit that is slightly smaller than the screws.

The number of screws you need will depend on the size of the flange. Most flanges require four screws to hold them in place.

Install the Screws

Once the holes are drilled, you can install the screws. You will need to use a screwdriver to tighten them in place. Be sure not to overtighten the screws as this can damage the flange and may cause the toilet to leak from the base.

Place the New Wax Ring on the Flange

Now that the flange is installed, you need to place the wax ring on top. The ring should fit snugly around the flange.

If you’re not sure which size wax ring to get, you can always ask a salesperson at the hardware store for help.

Set the Toilet Bowl in Place

Now that the wax ring is in place, you can set the toilet bowl in place. You will need to align the bolt holes with the holes on the flange. Once the bowl is in place, you can start to tighten the bolts.

Connect the Water Supply Line

The final step is to connect the water supply line to the toilet. You will need to screw the line into the fitting on the bottom of the tank.

Once the line is tight, you can turn on the water supply and flush the toilet to check for leaks. If there are no leaks, then you’re done! You’ve successfully installed a toilet flange.

If you want to know more about the entire toilet installation process, from removing to installing a new toilet, you can check out our article about How to Remove a Toilet and Replace It With a New One.

Conclusion

Installing a toilet flange is a relatively easy do-it-yourself project. Just be sure to measure the flange and select the correct size. Also, you should remember is that the screws must be hand tight only; overtightening them may cause the flange to break.

However, if you have doubts about your plumbing skills, it’s always best to call a professional plumber to help you install your toilet flange or even your entire toilet. This can save you time, money, and headaches because they know how to do it quickly and efficiently.

If you live in Lower Mainland Canada and need a trustworthy and experienced plumber to install your toilet flange, Your Guy Plumbing is here to assist you 24/7. We offer toilet installation and repair, as well as other plumbing services to meet all of your needs.

Do you really like reading up on Toilet Flanges? Create feedback down the page. We would be delighted to listen to your opinion about this blog entry. We hope that you visit us again later on. Sharing is nice. Helping others is fun. I value reading our article about Fix a Broken Toilet Flange.

Schedule Services

Comments on “Toilet Flange Repair - Troubleshooting and Rectifying Common Issues”